Weterings Plastics, part of the Hexatronic Group, is making sustainability progress with its zero production-related waste initiative at its Netherlands facility. All of the waste from production is being reused in new products. In that way the company ensures that nothing goes to waste. Additionally, certified post-consumer recycled material reached 44% last year.

New products made from reused plastics

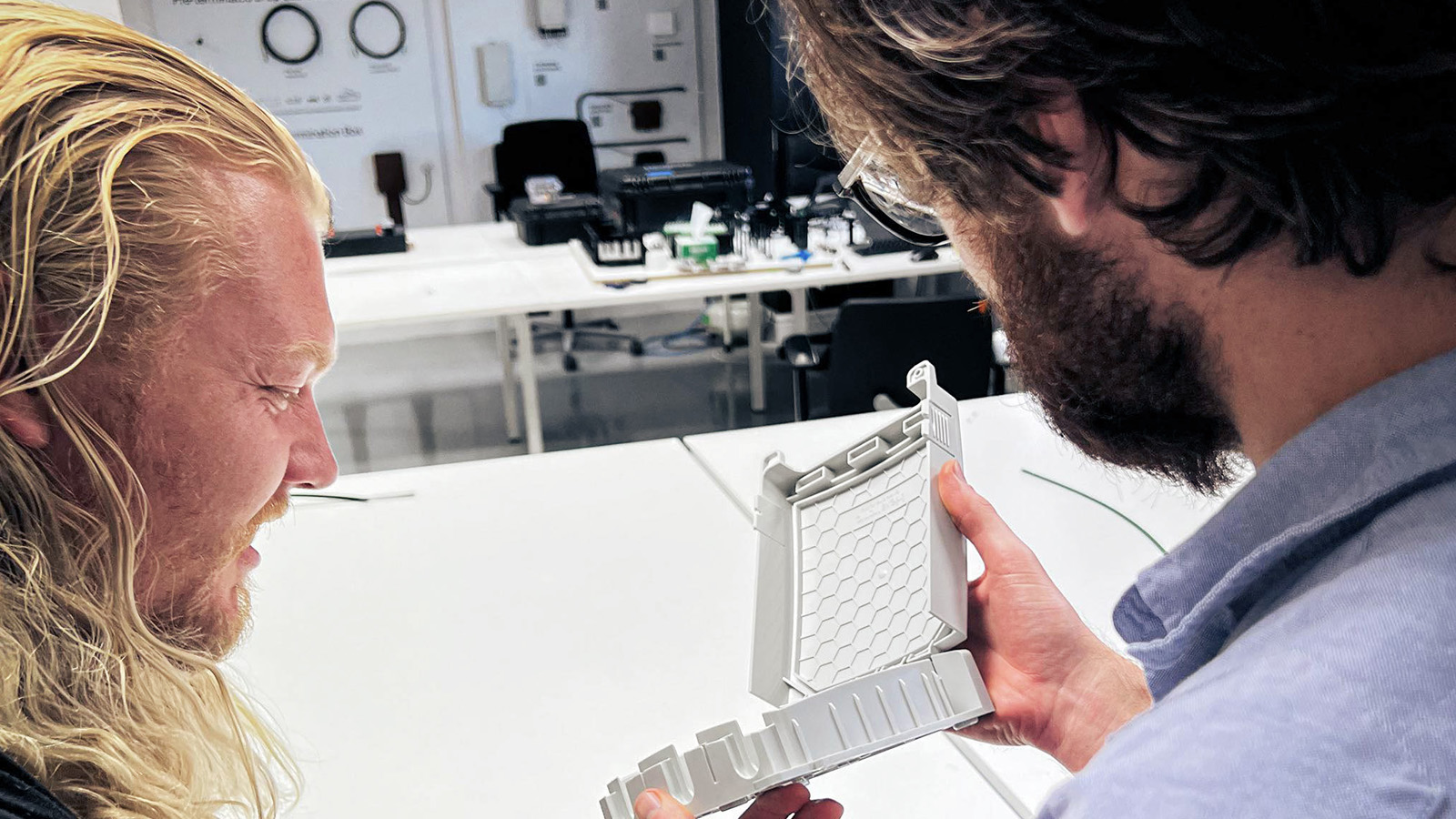

Fallout material is generated when machines start, stop, or switch materials. Instead of discarding it, Weterings reprocesses this material into granulates, which are then used to create new products. "Today, Weterings offers alternatives made from reused plastics for almost all our products. We can make products that have the same or even better properties than those made from virgin materials," says Thijs Rombouts, CEO of Weterings Plastics. "All materials that enter our factory go out as product. Of course, we have some general waste from packaging and running operations, like any business, but we have no access materials that go out as waste."

"We embrace Weterings Plastics' zero waste claim as an important circular initiative. Reusing all waste material from our production is essential in reducing the amount of virgin material."

Low carbon alternatives and client interest

Weterings Plastics has been committed to zero waste for as long as anyone can remember. This achievement is made possible by the company's diverse product range, which includes low carbon alternatives that utilize production outfall and post-consumer recycled materials. These innovative products include water hoses, three-layer telecom ducts, and full-body black micro ducts.

Clients are increasingly interested in these products due to their improved environmental performance. As acceptance for recycled products rises, Weterings Plastics has seen a significant increase in reused and recycled materials, with 44% of materials being certified post-consumer recycled last year.

Exploring more paths to reducing virgin material

Hexatronic is actively seeking more ways to decrease the use of virgin materials. In addition to incorporating reused production materials, we are increasing the amount of recycled polyethylene from other sources and testing prototypes made from renewable, bio-based raw materials.