The roof of our production facility in Neulengbach has been busy lately, with 852 new solar panels installed on top of several buildings. The panels will help run our duct production in Austria, reduce scope 2 emissions, lower costs, and make us more independent. We talked to the Plant Manager, Thomas Erb, about the project.

The plant in Neulengbach has a long production heritage, dating back to 1870 when the factory, one of the first in the area, produced varnish and paint. In 1958, the facility was acquired by REHAU, which initiated the production of ducts and conduits. Hexatronic took over the business in 2021 to secure local production and quick deliveries of ducts for the DACH area.

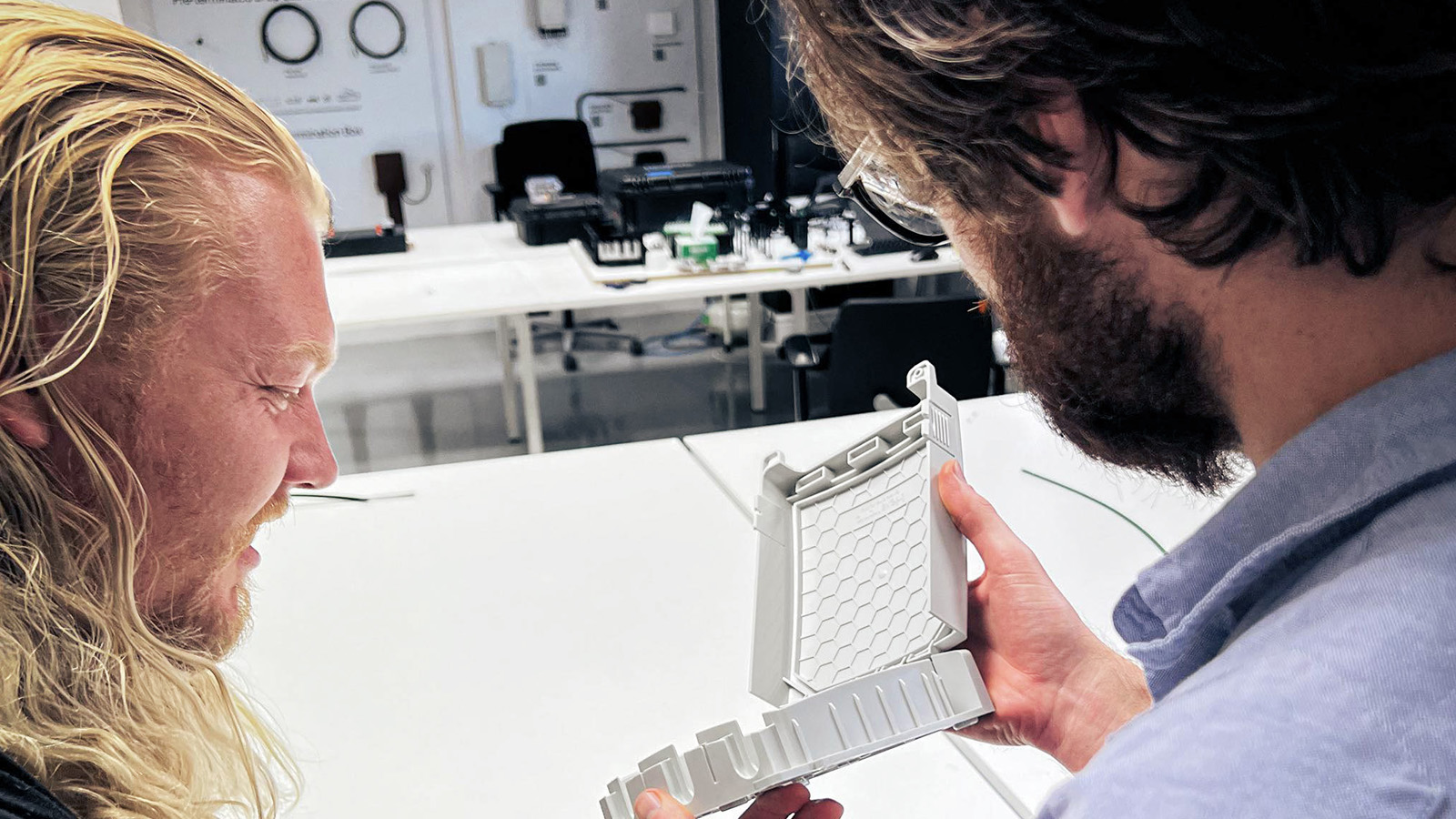

Our ducts serve as a protective pathway for our fiber optic cables and play a crucial role in our complete end-to-end solutions for fiber networks. To minimize transportation, Hexatronic always strives to produce ducts locally. The plant in Neulengbach ships high-quality ducts to network owners and telecom operators in Germany, Austria, and Switzerland, contributing to a more connected society.

Why is the solar panel project important?

"The solar panel project is a way for us to reduce carbon emissions, even though we are already using green electricity from sources like hydropower and wind power," says Thomas Erb. "The project will also reduce costs, make us less dependent, and strengthen our reputation as a sustainable player in the fiber network infrastructure business. The 852 panels will contribute to roughly 5% of the electricity consumed at the facility, and when the plant is closed on weekends, the energy produced supports the local grid. For this project, Hexatronic cooperates with the local energy company and invites the employees to invest in the panels for a safe investment in CO2-free energy production."

"In the future, we can utilize electricity created within our facility, and we plan to replace the diesel-driven forklifts and car fleets with electric vehicles. Lowering energy consumption is another way to minimize our impact on the environment. LED lights are now installed almost throughout the facility to reduce consumption. Moreover, we have already utilized the warm water from the extrusion process to heat the buildings, but in the next step, we are evaluating replacing gas heating with infrared technology." Thomas Erb explains. With all the ongoing and planned activities, Thomas believes the Neulengbach facility can be carbon neutral by 2027, three years earlier than the Hexatronic Group targets.

"The solar panel project in Neulengbach is an excellent example of how we can work toward our target of carbon-neutral operations by 2030. Reducing scope 2 emissions will, in turn, help our customers to reduce their scope 3 emissions."

Pernilla Eriksson, Head of Sustainability Hexatronic Group.

Read more about our Operations, or visit Sustainability at Hexatronic for more sustainability stories.