A successful FTTH project is a complex operation requiring excellent engineering skills, in-depth technical knowledge, practical hands-on skills, and lots of experience. Since a network owner rarely has this know-how, it is common to rely on engineering consultants and sub-contractors for projecting and installing a fiber optic network. As a result, decisions may not always be optimal for the investor, but instead, decisions may be biased by the preferences of consultants or sub-contractors.

Yet, there is some general advice for the investor to consider when budgeting and planning:

Installation cost

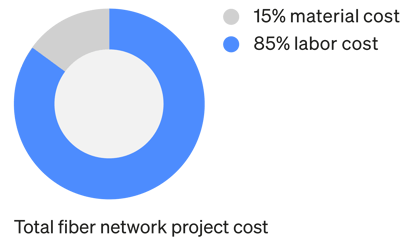

Installation cost is substantial since installing takes time and is labor-intense. Typically, the cost of materials is only a fraction of the labor cost. Accordingly, it is a good idea to keep labor cost down – if it is possible to do without affecting quality. A way to achieve this is to select methods and high-quality material that makes installation easier and faster. The slightly increased cost for materials and tools will pay off several times by the savings in labor cost.

Reducing Total Cost of Ownership

When planning a network, it is common to budget for installation and then separately budget for operation, including service and maintenance. When budgeting for installation, this cost is divided into:

- Cost for materials (typically 15-20%)

- Cost for labor (typically 80-85%)

In bigger organizations, e.g., with a dedicated purchasing department, it is a natural routine to focus on price for materials. This does not require any specific knowledge from the purchaser, other than verifying that materials are according to the current technical specification. To the non-expert, labor cost is unquestionable since he cannot judge upon what is really the minimum to achieve good enough quality.

Money lever – 800% in return!

Spend one extra $ and get eight back!

Materials feature and labor usage for installation are closely interrelated. Accordingly, investing in a slightly more expensive system solution could pay off immensely due to the much faster and smoother installation process. Investing one extra $ or € in materials may give up to 800% or more in return by the substantial time and labor savings.

What should you compare?

Your final decision should be based on thorough analysis by technical expertise. Still, a general comparison of technologies will indicate which way to go.

How is this possible?

Let us look into this simple, yet effective example:

First, let us agree on the cost model assumption 85/15 which means 85% of the total project cost is related to installation and 15% is related to the materials (cables, ducts, closures, manholes etc.).

Next, let us understand that the most common mistake when purchasing is to not consider the cost for materials and labor as one inseparable cost for installation. Choosing a high-quality easy-to-install system solution will substantially lower the total cost of ownership – not only by the installation but also when maintaining and upgrading the network during its entire lifetime. By using smart solutions with products that are installation optimized in such way that you save time when doing the installations, you obviously save money.

You may pay a small premium for an installation optimized system compared to the lowest cost products available. In this example we can assume that this premium can be around 5-10%, e.g. the cost of materials for a project will be 5-10% higher than the lowest bidder.

What can we expect when paying a premium of, 5-10%? Amongst others, you may get cables with better performance and longer expected lifetime, but let’s focus on installation cost. Generally, when speaking about proven and proper installation optimized systems, the savings in installation cost is expected to be around 10-25% or more! For now, take this as a fact. Later we will investigate how this is possible.

Let us calculate. We start with the 85/15 rule. We assume a premium of 6% on the materials and as a result of that, a conservative saving of 10% on the installation. This example gives us the new, optimized ratio of 76.5/15.9 (85 reduced by 10%, 15 increased by 6%).

When comparing this new ratio to the original 85/15 you see that the additional 0.90 you pay for the material gives you a total saving of 7.60 in total cost. This is a respectable 8% total project saving. However, if we investigate what you save (7.60) by paying a small premium for the materials (-0.90), this gives you an 800% return! The extra $ or € spent on installation optimized materials will give you eight back in savings on installation!

"The costs for materials and labor should be considered as inseparable – their interdependence is the basis for effectively reducing installation cost."

So, is this model linear? If you pay two extra $ or € for the material, will you get 16 times back? Of course not. There is a limit of possible savings because the installation cost cannot be reduced to zero. The above example is intended as a mathematical exercise to show that focus shall always be to minimize installation cost by using installation optimized materials, and by doing so, the savings will be huge!

What is an Installation Optimized System?

Yes, huge savings can be achieved if using system solutions that are installation optimized. So, what is an installation optimized system and how can we show that these actually saves time and money?

A set of materials and methods for fiber optic network installation that helps you to obtain the lowest Total Cost of Ownership (TCO) is considered to be an installation optimized system.

When installing fiber optic cables, there are several parameters that minimizes the TCO. Some of them are based on fastest possible installation:

- Use techniques that eliminate or minimize time consuming splice points, such as air blown micro cables and microducts

- Use cables designed for longest possible installation lengths by blowing

However, the TCO and installation cost is also determined by other parameters such as:

- Extra robust cables - Minimizes number of installation and operation errors

- Super low-loss cable design – Longest possible distance without costly signal regeneration

Let us look at some examples:

Fastest Installation - Longest Blowing Distances

One of the most important factors for lowering the TCO is to use an installation optimized cable that allows for longest possible installation distances.

Most Robust Cables – Minimum Number of Errors

Fiber optic cables, particularly micro cables, can be designed in many ways, A cable design with maximum robustness gives several advantages:

- Lower installation cost due to less fiber breaks during installation – The tubes does not kink during installation

- Extra slim design for smooth installation in ducts with low inner diameter, still robust

- Superior performance and widest possible operational temperature range (- 45 to +70 °C)

- Small bending radius, down to 30 mm

- Highest possible impact resistance

In case studies, A robust and installation fail-safe design, reduce the overall probability of an error during splicing and handling that corresponds to typically 7% lower splicing cost. The calculations are out of scope for this short summary but are easily accepted by an experienced installer.

Typical savings when splicing extra robust Micro Cables.

Best Optical Performance – Longest Possible Distance

Optical cables also differ in other ways. Cables with premium fibers, selected for best possible optical performance also gives lower TCO. As an example, typical attenuation values in premium cables are as low as 0.18 dB (@ 1550 nm) in cable. Such low values are almost non-existent in standard cables. In premium cables with low loss, this is a clear benefit for long distance network planning since the number of active repeaters can be minimized.

So, what about savings when using ultra low loss cables?

A typical case can be based on a 0.03 dB difference in typical attenuation between a premium cable and a standard cable.

For an installation length of 1000 km, this results in 30 dB attenuation difference. These 30 dB can be converted into a cost for adding active repeaters to compensate for this extra attenuation. Depending on transmission system used, distances etc., this cost may be reduced with up to 10-20% or more when using the ultra-low loss Viper series of cables.

Typical savings when using ultra-low loss Micro Cables.

Other factors that affects the Total Cost of Ownership

There are numerous other examples that affect the TCO. When looking at offerings from different vendors, it is unlikely that you won’t find several more or less trustworthy claims about performance and cost savings. As a network owner or investor, it is of course hard to separate the non-essential features from the essential features that really affects the TCO.

So, what shall you do? One suggestion is to spend time in the field during installation. Make notes of what is working and what is not.

- Did your team spend another day or two to blow in a cable because the cable did not pass through the planned distance?

- Was the cable installed properly but the final test showed that the weak cable was accidentally broken, and a section has to be re-installed?

- What about splicing time in closures? Does the installer enjoy their work, or do they have to work slowly to avoid breaking fiber tubes?

The savings can be indicated in theory, but the truth is found in real life!

Learn more about FTTH technologies and business from our experts.

This article was originally published in December 2020 and has been updated with minor edits.